History (2004): IBM Millipede

Based on MEMS (Micro Electro Mechanical Systems), micro-motors on chip

By Jean Jacques Maleval | February 13, 2019 at 2:26 pmAt CeBIT 2005, one storage product rose from the ashes: IBM’s Millipede.

Millipede is not based on any storage technologies known before now, be they magnetic, optical or flash, or even holography, FRAM or MRAM, the impending greatness of which we’ve been hearing about for so long now, we’re beginning to wonder.

You could not liken it to flash technology, since it is exclusively chip-based, but in fact, it isn’t at all the same thing. It is essentially mechanical, based on MEMS (Micro Electro Mechanical Systems), micro-motors on chip.

“We are now at 1Tb per square inch“,” told us at CeBIT Dr. Christoph Hagleitner, working at the IBM Zurich Research Laboratory, on a project whose beginnings date back to 1996. It’s the equivalent of nearly 100GB on a surface area the size of a postage stamp. Which means it has nearly ten times the areal density of the best HDDs currently available at this time.

Why Millipede stands a better chance of reaching the market than every other storage technology not based on magnetic and optical media that never gets past the research stage?

For at least two reasons:

- IBM officially introduced it at CeBIT as a ‘technology product,’ showing a prototype with a video-microscope offering a look inside the storage unit.

- Somewhat related to the previous reason, it is Big Blue we’re talking about that’s backing the project, and not one of the many start-ups that scratch away with limited means hoping to revolutionize the storage industry.

In addition to its extremely high capacity, the Millipede’s overall performance is also quite impressive: “An access time comparable to flash, i.e. a few milliseconds, a transfer rate greater than 20Mb/s, and at least 100,000 cycles of overwriting like flash,” according to Hagleitner.

He sees the Millipede more likely competing against tiny disk drives than with the flash memory used in mobile phones and digital cameras. It therefore doesn’t seem as though the new technology will be mobilized to take on the high capacities of desktop, enterprise or even notebook units, no doubt to its price, which is “competitive with flash.” The prototype we saw was outfitted with a SmartDisk form factor.

It remained to be seen whether IBM will decide to forge ahead with this new nanotechnology, which requires major investment, in particular for the MEMs manufacturing. Hagleitner said that the technology will be ready to appear on the market in two or three years. It didn’t.

Mllipede tehnnology

The code named Millipede comes from the fact that this storage technology resembles that of a creature of that name moving about and writing a little bit at a time. IBM has also compared to the old punch cards, a less astute observation, however, since not only can one make ‘holes’ here, but also close them up again, in order to read, write and overwrite.

At the heart of Millipede, there are two components:

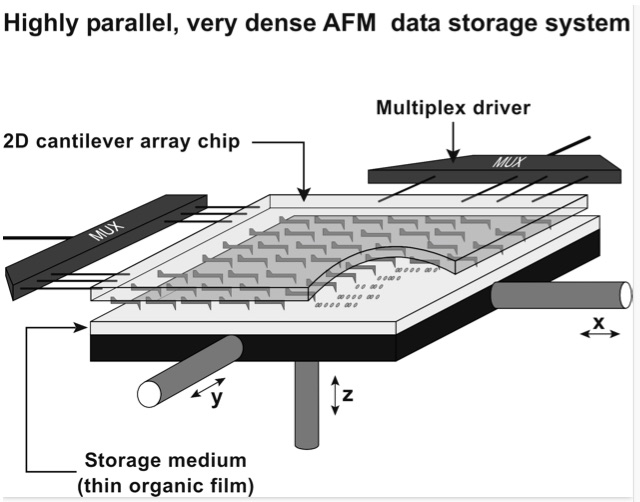

1) a two-dimensional array of 64×64 silicon probes or cantilevers

Each cantilever is 70µm long with a 500 to 700nm long tip. There are 4,096 (64×64) of these tips on a square surface 6.4mmx6.4mm, fabricated on a 10mmx10mm silicon chip. Each tip will be able to create or erase a marking by heating its storage medium, with each marking representing an individual bit.

2/ the moving storage medium

This consists of a polymer coated on a silicon substrate that is able to move on an X and Y grid under the tip array. This medium of 6.8mmx6.8mm in dimension is moved by a micro-mechanical scanner.

The array chip and storage medium with its micro-scanner are assembled together into a thin sandwich. This MEMS assembly is mounted on a PCB, and wire bonding technology is used to make electrical connections between the MEMS assembly and the circuit board.

Writing

Thermo-mechanical writing is performed by locally softening the polymer media using the heated tip of a cantilever and simultaneously applying force to create a nano-scale indentation in the polymer film. The tip is heated by applying a current pulse to a resistive heater integrated within the cantilever, directly behind the tip. During writing, the tip is heated to a temperature above the glass transition temperature of the polymer and force on the order of a few hundred nanonewtons is applied to the tip for a few microseconds.

Reading

Read-back of the data is performed using a thermo-mechanical sensing technique in which a second resistive heater integrated into the cantilever is heated to a temperature of around 200°C while the polymer medium is scanned under the tip. The principle of thermal sensing is based on the fact that the rate of cooling of this heater increases as the distance is reduced between it and the substrate carrying the polymer medium. Thus, when the tip moves into an indentation, the distance between the heater and substrate is reduced, resulting in an increase in cooling and hence a decrease in the temperature of the heater. This change in temperature results in an increase in resistance of the heater, which is detected by monitoring the current flowing through it.

Erasing

Erasing is essentially similar to writing at a narrower pitch between indentations. In the thermal-mechanical writing process described above, indentations are created by elastically straining the locally softened polymer by applying a force. This stress is then frozen into the film by rapidly cooling the material, resulting in the creation of a ‘meta-stable’ indentation. If the polymer is reheated, the polymer softens, thereby allowing the stored elastic strain to relax, and hence erasing the indentation. This can be done at the individual bit level by using the tip as a localized heat source. For example, writing a new indention very close to a previous one results in the erasure of the old indentation and the creation of a new one. Hence, a previously written data track can be erased simply by overwriting it with a series of closely spaced indentations.

Read also:

Millipede – an ultra dense data storage technology

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter