From Tohoku University, New Material Shows Promise for Next-Gen Memory Technology

NbTe4 phase-change material demonstrated switching speed of 30 nanoseconds.

This is a Press Release edited by StorageNewsletter.com on July 21, 2023 at 2:01 pmPhase change memory is a type of nonvolatile memory that harnesses a phase change material’s (PCM) ability to shift from an amorphous state, i.e., where atoms are disorganized, to a crystalline state, i.e., where atoms are tightly packed close together.

This change produces a reversible electrical property which can be engineered to store and retrieve data. Whilst this field is in its infancy, PCM could potentially revolutionize data storage because of its high storage density, and faster RW capabilities. But still, the complex switching mechanism and intricate fabrication methods associated with these materials have posed challenges for mass production.

In recent years, 2D Van Der Waals (vdW) transition metal di-chalcogenides have emerged as a promising PCM for usage in phase change memory. Now, a group of researchers from Tohoku University, Japan, has highlighted the potential use of sputtering to fabricate large-area 2D vdW tetra-chalcogenides. Using this technique, they fabricated and identified an exceptionally promising material – niobium telluride (NbTe4) – that exhibits a -low melting point of approximately 44 ºC (onset temperature), setting it apart from other TMDs.

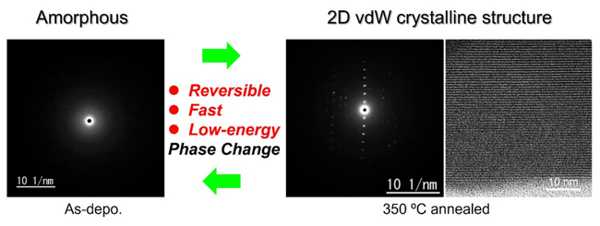

“Sputtering is a widely used technique that involves depositing thin films of a material onto a substrate, enabling precise control over film thickness and composition,” explains Yi Shuang, assistant professor, Advanced Institute for Materials Research, Tohoku University, and co-author of the paper. “Our deposited NbTe4 films were initially amorphous, but could be crystallized to a 2D layered crystalline phase by annealing at temperatures above 272ºC.“

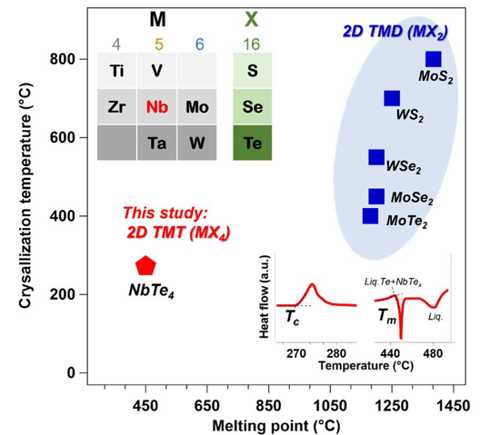

Unlike conventional amorphous-crystalline PCMs, such as Ge2Sb2Te5 (GST), NbTe4 demonstrates both a low melting point and a high crystallization temperature. This combination offers reduced reset energies and improved thermal stability at the amorphous phase.

Comparison of Tc (crystallization temperature) and Tm (melting point) values of various 2D TM chalcogenides; The Tc and Tm values of NbTe4 were defined by the onset temperature of crystallization and melting peaks in this study.

(©Yi Shuang et al.)

After fabricating the NbTe4s, the researchers then evaluated its switching performance. It exhibited a significant reduction in operation energy compared to conventional phase-change memory compounds. The estimated 10-year data retention temperature was found to be as high as 135ºC – better than the 85ºC of GST – suggesting an excellent thermal stability and the possibility of NbTe4 to be used in high-temperature environments such as in the automotive industry. Additionally, NbTe4 demonstrated a fast-switching speed of approximately 30 nanoseconds, further highlighting its potential as a next-gen phase change memory.

“We have opened up new possibilities for developing high-performance phase change memories,” adds Shuang. “With NbTe4’s low melting point, high crystallization temperature, and excellent switching performances, it is positioned as the ideal material to address some of the current challenges face by current PCMs.”

Details of the group’s discovery were published in the journal Advanced Materials on June 20, 2023.

A selected area electron diffraction and crossectional TEM image

of as-deposited and 350℃ annealed NbTe4 thin films.

(©Yi Shuang et al.)

Article: NbTe4 Phase-Change Material: Breaking the Phase-Change Temperature Balance in 2D van der Waals Transition-metal Binary Chalcogenide- Advanced Materials has published an article written by Yi Shuang, WPI Advanced Institute for Materials Research, Tohoku University, 2-1-1 Katahira, Aoba, Sendai, 980-8577 Japan, Qian Chen, New Industry Creation Hatchery Center, Tohoku University, 6-6-10 Aoba, Aramaki, Aoba-ku, Sendai, 980-8579 Japan, and Institute for Materials Research, Tohoku University, 2-1-1 Katahira, Aoba-ku, Sendai, 980-8577 Japan, Mihyeon Kim, Yinli Wang, Department of Materials Science, Graduate School of Engineering, Tohoku University, 6-6-11 Aoba-yama, Sendai, 980-8579 Japan, Yuta Saito, Shogo Hatayama, Device Technology Research Institute, National Institute of Advanced Industrial Science and Technology (AIST), Tsukuba Central 2, Umezono 1-1-1, Tsukuba, 305-8568 Japan, Paul Fons, Department of Electronics and Electrical Engineering, Faculty of Science and Technology, Keio University, 3-14-1 Hiyoshi, Kohoku-ku, Yokohama, Kanagawa, 223- 8522 Japan, Daisuke Ando, Department of Materials Science, Graduate School of Engineering, Tohoku University, 6-6-11 Aoba-yama, Sendai, 980-8579 Japan, Momoji Kubo, Institute for Materials Research, Tohoku University, 2-1-1 Katahira, Aoba-ku, Sendai, 980-8577 Japan, and New Industry Creation Hatchery Center, Tohoku University, 6-6-10 Aoba, Aramaki, Aoba-ku, Sendai, 980-8579 Japan, and Yuji Sutou, WPI Advanced Institute for Materials Research, Tohoku University, 2-1-1 Katahira, Aoba, Sendai, 980-8577 Japan, and Department of Materials Science, Graduate School of Engineering, Tohoku University, 6-6-11 Aoba-yama, Sendai, 980-8579 Japan.

Abstract: “Two-dimensional (2D) van der Waals (vdW) transition metal di-chalcogenides (TMDs) have garnered significant attention in the nonvolatile memory (NVM) field for their tunable electrical properties, scalability, and potential for phase engineering. However, their complex switching mechanism and complicated fabrication methods pose challenges for mass production. Sputtering is a promising technique for large-area 2D vdW TMD fabrication, but the high melting point (typically Tm > 1000°C) of TMDs requires elevated temperatures for good crystallinity. This study focuses on the low-Tm 2D vdW TM tetra-chalcogenides (TMTs) and identifies NbTe4 as a promising candidate with an ultra-low Tm of around 447°C (Onset temperature). As-grown NbTe4 is forms an amorphous phase upon deposition that can be crystallized by annealing at temperatures above 272°C. The simultaneous presence of a low Tm and a high crystallization temperature Tc can resolve important issues facing current phase-change memory compounds, such as high Reset energies and poor thermal stability of the amorphous phase. Therefore, NbTe4 holds great promise as a potential solution to these issues.“

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter