FMS: SK hynix Develops 238-Layer 512Gb TLC 4D NAND Flash

Up to 2.4Gb/s transfer speed, 50% increase from previous gen, and volume of energy consumed for data reading decreasing by 21%

This is a Press Release edited by StorageNewsletter.com on August 8, 2022 at 2:03 pmSummary :

-

First 238-layer 512Gb TLC 4D NAND developed in July; expected to begin mass production in 1H23

-

Providing highest, smallest NAND product while improving productivity, data transfer speed and power efficiency

-

“Will continue innovations to find breakthroughs in technological challenges“

SK hynix Inc. developed a 238-layer NAND flash product.

It has recently shipped samples of the 238-layer 512Gb TLC(1) 4D NAND product to customers with a plan to start mass production in the first half of 2023.

“The latest achievement follows development of the 176-layer NAND product in December 2020,” the company stated. “It is notable that the latest 238-layer product is most layered and smallest in area at the same time.”

The company unveiled development of the latest product at FMS (2) in Santa Clara, CA.

“SK hynix secured global top-tier competitiveness in perspective of cost, performance and quality by introducing the 238-layer product based on its 4D NAND technologies,” said Jungdal Choi, head, NAND development, in his keynote speech during the event. “We will continue innovations to find breakthroughs in technological challenges.”

Since development of the 96-layer NAND product in 2018, the firm has introduced a series of 4D products that outperform existing 3D products. It has applied Charge Trap Flash (3) and Peri Under Cell (4) technologies to make chips with 4D structures. 4D products have a smaller cell area per unit compared with 3D, leading to higher production efficiency.

The product, while achieving highest layers of 238, is the smallest NAND in size, meaning its overall productivity has increased by 34%, compared with the 176-layer NAND, as more chips with higher density per unit area can be produced from each wafer.

The data-transfer speed of the 238-layer product is 2.4Gb/s, a 50% increase from the previous generation. The volume of the energy consumed for data reading has decreased by 21%, an achievement that also meets the company’s ESG commitment.

The 238-layer products will be first adopted for client SSDs which are used as PC storage devices, before being provided for smartphones and high-capacity SSDs for servers later. The company will also introduce 238-layer products in 1Tb next year, with density doubled compared to the current 512Gb product.

(1) TLC: NAND flash products are categorized into Single Level Cell, Multi Level Cell, Triple Level Cell, Quadruple Level Cell and Penta Level Cell depending on the number of information (unit: bit) contained in a single cell. That a cell contains more information means more data can be stored within the same extent of area.

(2) FMS: The world’s biggest conference for NAND flash industry taking place in Santa Clara, CA, every year. During its keynote speech at the event SK hynix made a joint announcement with Solidigm.

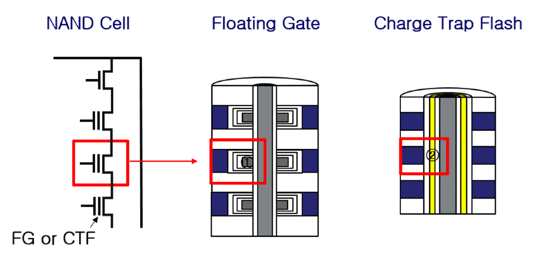

Principle of Charge Trap Flash technology

(3) Charge Trap Flash (CTF): Unlike floating gate, which stores electric charges in conductors, CTF stores electric charges in insulators, which eliminates interference between cells, improving RW performance while reducing cell area per unit compared to floating gate technology.

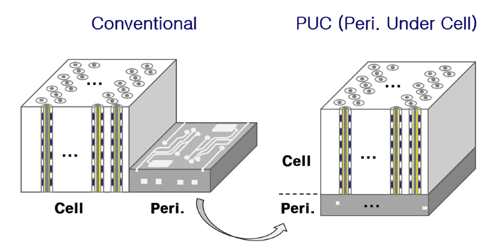

Principle of Peri. Under Cell technology

(4) Peri. Under Cell (PUC): A technology that maximizes production efficiency by placing peripheral circuits under the cell array.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter