History (1997): Platoon of Young Women at Read-Rite Head Stack Assembly Plant

"Yield is a challenge" for manufacturing

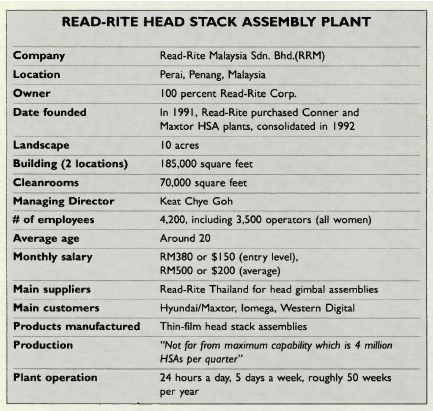

By Jean Jacques Maleval | September 21, 2021 at 1:31 pmRead-Rite Malaysia (RRM), in Perai, Penang, a wholly-owned subsidiary of Read-Rite Corp. (RRC), manufactures high-volume head stack assemblies (HSAs) suited to some 50 different applications for the majority of the company’s disk drive customers and is, to this end, strategically located near the firm’s plant in South East Asia.

RRC is the world’s leading independent manufacturer of recording heads, head gimbal assemblies (HGAs) and HSAs for disk drives and MR heads for QIC tape drives.

The company is headquartered in Milpitas, CA, and has operations in Japan, Thailand, Malaysia, The Philippines and Singapore.

Read-Rite SMI is a joint venture between RRC and Sumitomo Metals and has a wafer fab in Osaka, Japan.

Read-Rite employs some 20,000 people.

In October of 1991, Read-Rite acquired Conner Peripheral’s HSA plant, situated in Penang. Then, 2 months later, it took over Maxtor’s HSA facility, now occupied by RRM. In April of 1992, Read-Rite decided to consolidate these 2 factories into their present location.

RRC now produces 4 million 3.5-inch HSAs per quarteri its factories in The Philippines and Penang. To be more precise, RRM now occupies 2 sites in Perai, close together: the first and smaller of the 2, only 30,000 square feet, faces directly across from SyQuest (who does not deal with Read-Rite), while the other, with 155,000 square feet of class 100 cleanrooms where about 3,500 young women, dressed from head to toe in white, work with painstaking detail, eyes glued to their microscopes, all aligned with by rows of tables That seem endless. The workers are divided in to 3 shifts per day, 5 days a week, according to our guide. Aloysius K. K. Cheang, senior director of finance at RRM.

The principal components of the HSAs manufacrued here are HGAs, Flex Ciruit Board Assemblies (FCBAs), Actuator Coil Assemblies (ACAs) and bearings HGAs come from RRC’s Thai facility, and these are either shipped directly to heir customers or to RRM for HSA manufacturing. Read-Rite Thailand is also in charge of slider production, while wafer manufacturing takes place in California and Japan.

The other components are produced either locally or from within Asia.

Read-Rite is best known as a manufacturer of magnetic disk heads, it’s worth noting all the same that the greatest part of its revenues come from assembles modules, be they HGAs (33% of the firm’s turnover for the quarter ending last December) or, more predominantly), HSAs (53%).

What is Head Stack Assembly or HSA?

Before HSA, Head Gimbal Assembly or HGA consisted of placing the thin-film head slider and wires onto a metal suspension.

A lot of HGAs produced by Read-Rite are assembled into head stack assemblies or HSAs prior to shipment to customers.

At RRM, the HGAs are swaged onto an ACA of which an FCBA is attached. Dynamic testing requires the HSA to be mounted on a spindle which contains several disks to simulate the performance of the HSA as if it was in a disk drive by reading and writing from/to the HGA and disk.

This article is an abstract of news published on the former paper version of Computer Data Storage Newsletter on issue 111, published on April 1997.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter