History (1994): Visit of Hewlett-Packard Storage Manufacturing Plant in Bristol, UK

Producing DAT, HDD and subsystems, optical libraries and QIC drives

By Jean Jacques Maleval | December 29, 2020 at 2:11 pmThe plant is located near Bristol, UK, in a small town full of history and surrounded by pretty green countryside.

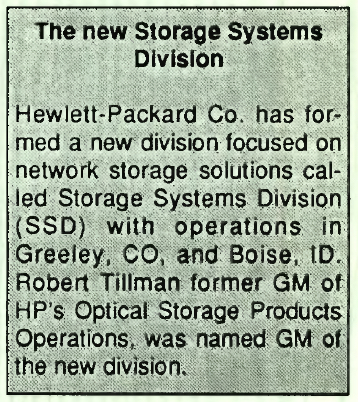

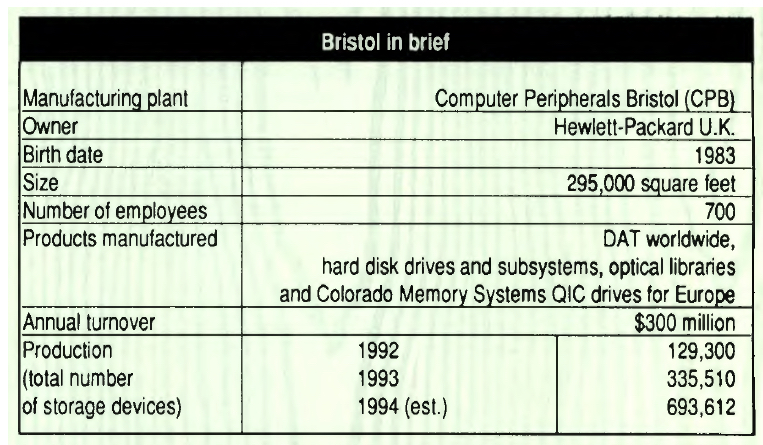

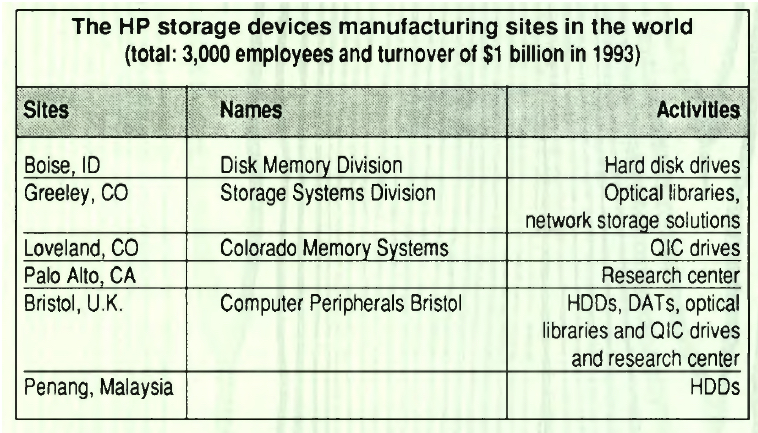

Computer Peripherals Bristol (CPB) was formed in 1983. It’s one of several HP’s divisions in the country and is part of the HP Mass Storage Group.

CPB, with 700 employees in a 295,000 square foot building, has WW responsibility for design, manufacturing and marketing of DDS format DAT drives and is the European marketing center for all the mass storage products.

Additionally, a small manufacturing line of HDDs, disk drive subsystems and optical libraries, as well as a small assembling unit for Colorado Memory Systems QIC drives for Europe are located there.

According to John Gannon, GM of CPB, the WW mass storage activity for HP was over $1 billion for 1992 and over $1.5 billion is planned for this year. The two thirds of these amounts result from HDD sales.

“In 1992, over 60% of the production went to other companies than HP. Last year, it was over 80% and it will reach 90% at the end of the 90’s,” he said.

In 1993, he mentions that Bristol’s CPB’s turnover was $300 million, a little less than one third of the entire mass storage activity of the US company.

As much HP is well known for its peripherals like printers, scanners or plotters, as little it is for its storage products.

“It’s our best kept secret in the company,” remarked Geoff Kirk, reseller channel manager in Bristol.

The first product manufactured here, in November 1984, was the Buffalo, a quarter-inch DC600 cartridge drive storing 16MB based on a proprietary format. Exactly 85,835 samples were produced in this plant.

In the small clean room of this factory is produced the Wolverine II (or C2247), a 3.5-inch full height 1GB HDD.

According to one of the plant’s executives, one drive is produced with 1,700 different parts in 30 hours with 22 hours just on tests.

The line employs 100 people and has a maximum production capacity of 9,000 HDDs per month.

The platters mainly come from Komag and the heads from PCI.

The next gen of manufactured disks will be the Wolverine III or C2490A with 2.1GB in the same form factor.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter