History (1990): Conner Close to Be $1 Billion Company

After just 3 years of business

By Jean Jacques Maleval | December 10, 2019 at 2:15 pmHow can you become the fastest growing start up in the US industry in a segment as crowded as the Winchester disk one?

Conner Peripherals Inc. (San Jose, CA) was incorporated in California in June 1985. It was formed by Finis Conner and John Squires to produce an innovative 3.5-inch drive directly, without going through the 5.25-inch form factor.

Finis F. Conner, 46 years old, had helped earlier to start Shugart Associates and Seagate Technology with Alan Shugart, but the first one stood in the shadow of the second one that became the leader of the largest independent Winchester manufacturing plant worldwide.

$700 million in 1989

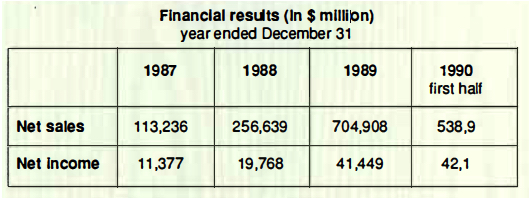

In just 3 years of operations, the company, that employs about 5,000 persons, earned over $700 million.

“We became only the second company ever to reach the ranks of the Fortune 500 in our third year of sales. In the processes, we also became the fastest growing manufacturing start-up in American business history,” wrote Finis Conner, chairman and CEO, in the last annual report of its company.

And nothing seems to stop this progress. In the first 6 months of fiscal 1990, which means at the end of last June, Conner reported $538.9 million sales, almost the double compared to the first half of 1989 ($294,8 million). And net income of the first six months, $42.1 million, is higher than the amount of the entire 89 fiscal year.

Last year, Conner produced 2.2 million drives, according to a spokesman of the company. “And we are going to double these figures this year,” he added.

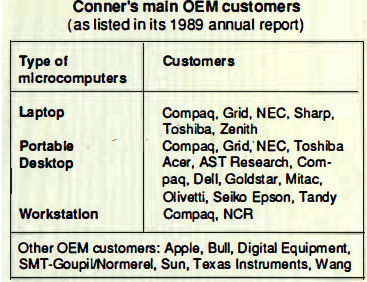

The number of OEM customers throughout the world jumped from 15 in 1988 to 40 in 1989, and around 80 are expected this year (see the partial list below).

Compaq’s help

In the mid-eighties, American venture companies were not very keen about a newcomer in an overcrowded business. Conner was lucky enough to find the support of the microcomputer manufacturer Compaq Computer Corporation, as this company was looking for this type of drive for its units.

Therefore Compaq acquired an equity interest in Conner during 1986. On December 31, 1989, Compaq owned approximately 32% of the outstanding capital stock and was entitled to elect one director.

In 1986, the two companies also entered in an agreement pursuant to which Conner agreed to sell its products to Compaq for a period of 6 years at the lowest price offered by or to any customer. The agreement also grants Compaq certain price protections and does not require minimum purchase quantities.

In addition, should Conner be unable to meet Compaq’s demand for its products, Compaq would have the right to manufacture or arrange for third party manufacture of these products itself under a royalty free manufacturing license.

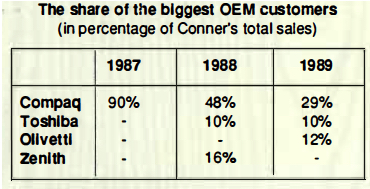

Compaq undeniably helped Conner start off by assuring 90% of its sales in 1987. This percentage dropped to 48 in 1988 and 29 in 1989.

Three other major customers should be mentioned: Olivetti, Toshiba and Zenith.

.

When you have a large range of customers, you have less risk when one of them has problems and you appear more trustworthy to other computer manufacturers.

Finis Conner has realized this and notes the evolution of his company in this way: “Conner’s greatest growth in 1989 came from international sales. By the end of the year(1989), approximately 43% of all revenues came from overseas customers, compared to approximately 22% in 1988. In particular, we have had a tremendous success selling into the Japanese market, where 5 of the top personnel computer manufacturers now use our disk drive products.”

The right timing

The US manufacturer success is based on two ideas: selling products before they are manufactured, and being the first one to mass produce the small HDDs required by OEMs.

After analyzing the customer’s need, prototypes are designed at the firm’s Colorado research center. A pre-production is then achieved in the San Jose HQ, then final production moves to Singapore.

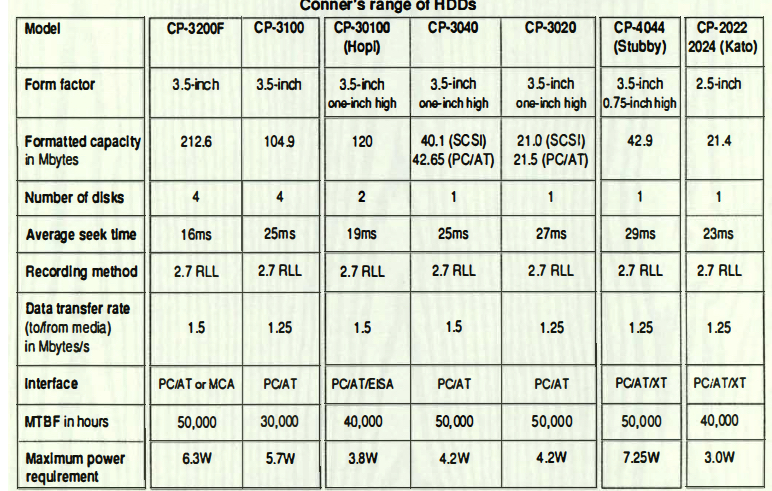

In two years, Conner launched 8 different HDAs, which is probably a record in Winchester business.

The CP-3020 marked the technology, with 21MBs in a low-profile (one-inch high) 3.5-inch form factor.

In the same volume, the CP-301 00 or Hopi stores 120MB.

The CP-4044 or Stubby is even more amazing, only 0.75 inches high. It provides 43MB of formatted storage capacity, weighs 13 ounces, requires 1.3W to operate, and is designed to withstand up to 100G of shock.

With JVC and PrairieTek, Conner is the only one to have announced and regularly produced a 2.5-inch HDD, the CP-2022- 2024, also named Kato.

Last March, speaking of them, Scott Holt, executive VP, sales and marketing, said: “We have shipped 30,000 at the end of the month.“

For the future, Conner engineers are working on disk arrays. Compaq was one of the first companies to develop this technology using Conner’s drives with the introduction of its SystemPro products in late 1989.

R&D expenses in 1989 increased substantially, representing 5.6% of net sales, as compared to 3.4% in 1988 and 3.1% in 1987.

A problem: the access to components

Main HDD components, like platters and magnetic heads, motors, etc, are bought from subcontractors by Conner. And it can be hazardous not to handle the entire production line. On account of shortage in supplies, Conner cannot face the growing demand of small drives for laptop and notebook computers. The company prefers to satisfy its large OEM customers, leaving many small customers and distributors unhappy.

But it’s the same for PrairieTek that can neither face the demand.

An example of component supply problem was recently reported. When Seagate acquired Imprimis and its subsidiary PCI, a manufacturer of thin-film heads, Seagate wanted to renegociate the agreement between PCI and Conner. Finis Conner and Alan Shugart are not true friends. Seagate, Conner’s largest competitor, tried to trouble Conner Peripherals. This latest one replied with a lawsuit filed last April. Finally, like well-mannered businessmen, they reached a friendly agreement.

But this episode didn’t help Conner. The agreement with Olivetti only led to losses. In July 1 988, the Californian firm entered into a joint venture with Ing. C. Olivetti& C., SpA to manufacture and sell 40 and 100MB drives in Europe. The joint venture has been named Conner Peripherals SpA (CPE) and is based in Italy. The agreement provides that Conner will at all times have management control of CPE.

Initially, CPE was owned 49% by Conner and 51% by Olivetti. In July 1989, the US company increased its ownership interest to 51% and has an option to further increase it ownership to 100%. This option expires in July 1991. Additionally, Olivetti has a put option to require Conner to increase its ownership in CPE. Both options are exercisable at the current book value of CPE’s stock.

Since inception, Olivetti and Conner each have contributed approximately $4 million in cash. But this US/Italian agreement is no big success. During fiscal years 1989 and 1988, CPE recorded losses of $1.5 million and $1.2 million respectively. To have better results in Europe, Conner has decided to built its own plant, 40,000 square feet, in Scotland. According to Holt, the Italian plant will focus on high capacity 200MB drives, when the Scottish one will produce large volumes of 40MB disks. Conner also owns a manufacturing facility in Malaysia.

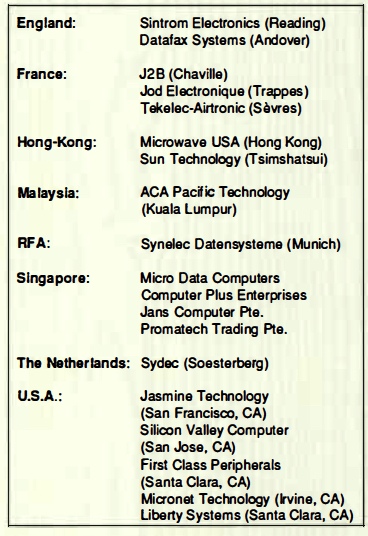

Some distributors of Conner’s drives

Here is a list of distributors of Conner Peripherals HDDs, taken from our personal files:

This article is an abstract of news published on the former paper version of Computer Data Storage Newsletter on issue ≠31, published on August 1990.

Note: Conner Peripherals grew to $2.7 billion in its 10th year and was acquired by Seagate for $1.04 billion in 1995.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter