R&D: Major Step Closer to Viable Recording Material for Future HDDs From Amity University

By tweaking iron-platinum alloy, group of researchers in India are trying to clear few hurdles slowing material’s viability as future perpendicular recording media.

This is a Press Release edited by StorageNewsletter.com on December 25, 2018 at 2:22 pmMagnetic recording is the primary technology underpinning today’s large-scale data storage.

Now, companies are racing to develop new HDDs capable of recording densities greater than one terabit per square inch.

Perpendicular recording HDDs store data as tiny areas of ‘up’ or ‘down’ magnetization within a thin layer on the surfaces of the disks. Each tiny area represents one bit of information, and increasing the areal density of recordings requires a reduction in bit size.

The catch is that the current magnetic recording media that rely on perpendicular cobalt-chromium-platinum (CoCrPt) oxide granular films are reaching their physical limit – a density of approximately 750 gigabits per square inch – because thermal fluctuations prevent shrinking the grain size below six to seven nanometers. In AIP Advances, from AIP Publishing, a group of researchers in India report their work tweaking the L10 phase, or crystallographic orientation, of an iron and platinum (FePt) alloy as a solution.

The L10 phase of the FePt alloy boasts high magnetocrystalline anisotropy, which means that it remains thermally stable even at grain sizes as small as three nanometers. But the material’s downside is that it requires a high annealing temperature (500°C to 600°C) to transform the deposited disordered phase into an ordered tetragonal L10 phase, raising the cost of manufacturing.

“The material’s need for such a high annealing temperature renders it incompatible with industrial processes, as well as causes significant grain growth and an increase in bit size — none of which is desirable,” said Ajay Gupta, director, Center for Spintronic Materials, Amity University (India).

This has resulted in a method developed by the authors which leads to a significant enhancement of the L10 transformation rate in FePt systems by lowering the ordering temperature below 300°C.

“This is a major step toward realizing L10 FePt as a material for high density perpendicular recording,” Gupta said.

L10 FePt as a perpendicular recording media may one day be able to increase the magnetic recording density in HDDs beyond one terabit per square inch.

“Our work overcomes one of the main challenges by reducing the ordering temperature,” said Gupta. “But there are still other crucial requirements – such as achieving the desired grain orientation – that must be met before it will become viable to use L10 FePt.”

The group is now pursuing a better understanding of the atomic-level mechanism for the enhancement of the L10 transformation rate in FePt, and trying to optimize the layer composition and thicknesses of the multilayer structure to achieve peak enhancement.

“We’re working on the desired grain orientation for producing perpendicularly magnetized media by selecting the proper underlayer of material over which FePt will be deposited,” Gupta said.

Article: Enhancement of L10 transformation in Fe/Pt multilayer by Cu addition

AIP Advances has published an article written by Kavita Sharma, Gagan Sharma, Amity Center for Spintronic Materials, Amity University UP, Sector 125, Noida 201 313, India, Mukul Gupta, V. Raghavendra Reddy, UGC-DAE Consortium for Scientific Research, University Campus, Khandwa Road, Indore 452 001, India , and Ajay Gupta,, Amity Center for Spintronic Materials, Amity University UP, Sector 125, Noida 201 313, India.

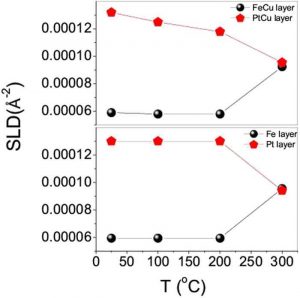

Variation in scattering length density of FeCu and PtCu layer

in M1 multilayer (top) and Fe and Pt layer in M2 multilayer (bottom).

Abstract: “Enhancement in L10 transformation kinetics in FePt is achieved by incorporating an optimum concentration of ternary element Cu, which has limited solubility in the fcc FePt phase, into the FePt multilayer stack. Two different multilayer structures were deposited. In first multilayer Cu is deposited at one interface of Fe/Pt and in other Cu is alloyed with Fe and Pt layers by co-sputtering. One Fe42.5Pt42.5Cu15 alloy film is also prepared and detailed study of evolution of structural and magnetic properties as a function of isochronal annealing is done using XRD and Magneto Optic Kerr Effect (MOKE) measurements respectively. Annealing up to 200oC results only in intermixing in the multilayer structure, with no sign of L10 transformation. Annealing at 300oC for 1h results in partial transformation to L10 phase as evidenced by appearance of (001) superlattice peak as well as large increase in the coercivity. It is found that in the Fe(Cu)/Pt(Cu) multilayer exhibits significantly faster L10 transformation as compared to Fe/Pt/Cu multilayer or FePtCu alloy film. Inter-diffusion study using x-ray reflectivity measurements reveals that constant for interdiffusion in Fe(Cu)/Pt(Cu) is only marginally higher than that in Fe/Pt/Cu multilayer. The observed enhancement in L10 transformation rate in Fe(Cu)/Pt(Cu) multilayer is discussed in terms of possible enhancement of diffusivities of constituent species in fcc FePt phase.”

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter