R&D: Nanostructure, Structural Stability and Diffusion Characteristics of Layered Coatings for HAMR Head Media

Investigation suggests that further optimization of developed layered coatings can provide viable solution to thermal damage of HAMR heads.

This is a Press Release edited by StorageNewsletter.com on July 31, 2018 at 3:17 pmScientific Reports has published an article written by J. Matlak, Department of Mechanical Engineering, University of California, Berkeley, CA, 94720, USA, E. Rismaniyazdi, Western Digital Company, San Jose, CA, 95119, USA , and K. Komvopoulos, Department of Mechanical Engineering, University of California, Berkeley, CA, 94720, USA.

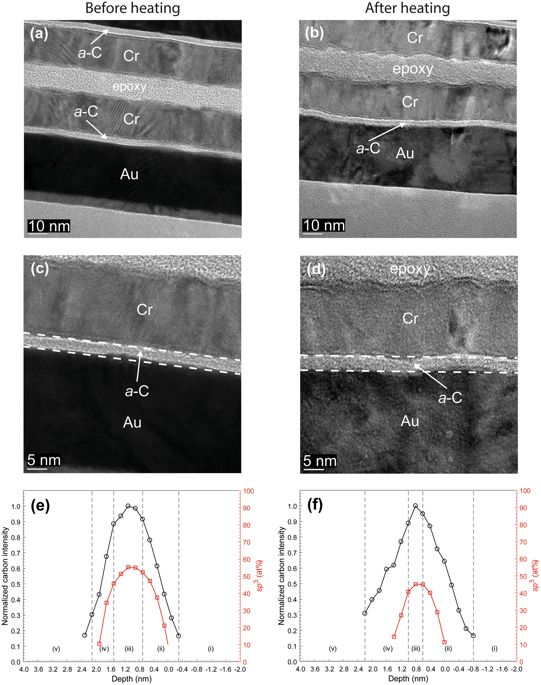

Figure 1: (a–d) Cross-sectional HRTEM images and (e,f) depth profiles of C K-edge normalized intensity and sp3 fraction calculated from C K-edge EELS spectra of industry sourced a-C overcoats deposited on a SiN/Au sample stack obtained before and after heating at 350 °C for 30 min in an Ar environment. (The EELS profiles show a layered cross-sectional nanostructure consisting of the following five regions: (i) underlayer, (ii) interface (intermixing) layer, (iii) bulk layer, (iv) surface layer, and (v) capping layer).

Abstract: “The intense laser heating in heat-assisted magnetic recording (HAMR) has been a major hindrance to HAMR technology from becoming commercially viable. Thermal damage of the near-field transducer (NFT) and write pole (WP) embedded in the trailing edge of the magnetic head due to failure of the protective carbon overcoat after prolonged heating at an elevated temperature are major obstacles. Therefore, the main objective of this study was to develop an effective coating method for HAMR heads. This was accomplished by introducing a new class of layered coatings consisting of ultrathin amorphous carbon (a-C) overcoat, adhesion (SiN) layer, and buffer (NiCr or TaOx) layer sequentially deposited onto Au and FeCo base layers to mimic the layer stacking of NFT and WP elements, respectively. The structural stability of the a-C overcoats and diffusion characteristics of each comprising layer under conditions of heating at 350°C for 30 min in an Ar atmosphere were investigated by high-resolution transmission electron microscopy (HRTEM), scanning transmission electron microscopy (STEM), and electron energy loss spectroscopy (EELS). For most stacking configurations the HRTEM/STEM and EELS results generally revealed some layer intermixing and minute carbon atom rehybridization in the heated a-C overcoats. The findings of this investigation suggest that further optimization of the developed layered coatings can provide a viable solution to thermal damage of HAMR heads.“

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter