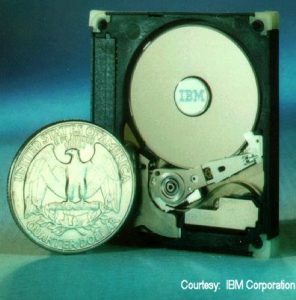

History (1999): IBM Microdrive

One-inch HDD at 170MB and 340MB

This is a Press Release edited by StorageNewsletter.com on June 28, 2018 at 2:33 pmThis article comes from WikiFoundry, Inc.

1999: IBM Microdrive

First One-Inch HDD

Significance

IBM introduced the one-inch Microdrive in 1999 with capacities of 170 and 340MB.

For a time, the IBM Microdrive and similar one-inch HDDs from IBM’s competitors achieved significant market share for storage in high end digital cameras and compact digital music players. Eventually, rapid progress in solid-state flash memory brought an end to one-inch HDDs.

Several major HDD players including Western Digital and Seagate produced one-inch HDDs. Start-ups that were funded primarily to develop 1 inch drives include Halo Data Devices, Marqlin, Microstor, RioSpring and Cornice.

Key players

Several IBM employees played key roles in the product and business development of the Microdrive.

The concept of the IBM Microdrive began in IBM Research at the Almaden Research Center in San Jose, CA. Tim Reiley, who is viewed as the ‘father’ of the Microdrive, envisioned a small form factor disk drive to provide high capacity storage for mobile devices. His original idea was that the Microdrive would exploit micro-electro-mechanical systems (MEMS) for the spindle motor, head actuator, and other components. Two Silicon Valley HDD start-ups (Halo Data Devices and Marqlin) received funding based on a similar vision of MEMS motor technology in microdrives.

Tom Albrecht, also at the IBM Almaden Research Center, collaborated closely with Reiley, and guided the project toward exploitation of miniaturized conventional technologies instead of MEMS, which would have had higher cost and technical risk.

Hideya Ino, leader of mobile drive development at IBM’s Fujisawa, Japan HDD development site, was the first influential executive within IBM to see the potential of the Microdrive. He directed a few members of his team to develop working prototypes in collaboration with research, and used the prototypes to help persuade the IBM HDD product planning and marketing teams to join him in supporting the project. Mitsuhiko Aoyagi and Kenji Kuroki were prominent among the many technical contributors from the Fujisawa development team that launched the actual product line.

Bill Healey and John Osterhout of the IBM storage technology division in San Jose were responsible for business development and marketing of the Microdrive.

Compatible with a Standard Storage Card Slot

One of the keys to the success of the IBM Microdrive was that it was designed to be compatible with the existing CompactFlash standard for removable data storage cards. At the time of the introduction of the Microdrive, CompactFlash had emerged as the leading standard among several competitors. Its HDD-like host interface also made it a natural choice for the Microdrive. There was one major problem; although the CompactFlash form factor was among the largest for removable storage cards used in cameras, its 3.3 mm thickness was too thin for an HDD.

Fortunately the CompactFlash Association was amenable to the creation of new variants of its standard, and a new working group of the association, chaired by Albrecht of IBM, defined and introduced the CompactFlash (CF) type II form factor. This standard defined the 5mm thickness needed for an HDD, and a new functional specification called CF Plus, with the needed power supply and command infrastructure to support the HDDs and other non-storage devices that were adopting the CF standard as well. The new standard was a success, with CF type II slots becoming commonplace in subsequent years.

Why did the Microdrive succeed when its precursor, the Hewlett-Packard Kitty Hawk, 1.3-inch drive did not? One of the main reasons was compatibility with the CF standard. Another reason was the more mature market for digital cameras and the emerging market for digital music players (see below).

Enabling Technologies

The technical success of the Microdrive was built upon optimal miniaturization of conventional components. Recent technical trends in mobile drives, including the use of ramp load/unload, inertia latches, and head gimbal assemblies with integrated wiring set the stage for the development of the Microdrive.

Ramp load/unload (a low-cost system for removing the heads from the disk surfaces when the spindle is powered off) was pioneered in the late 1960s by Memorex in its Model 630 disk drive (IBM 2311 plug compatible) and later used by Control Data Corporation, Integral Peripherals, PrairieTek, Quantum and SyQuest, amongst others.

IBM first introduced ramp load/unload in its TravelStar line of 2.5-inch mobile HDDs in 1997. Load/unload was vital for the Microdrive, because it would have been difficult to design a spindle motor compact enough for the Microdrive with sufficient torque to spin up the disk with the older contact start-stop system.

Although 2.5 -inch drives using load/unload could derive emergency power from the spinning spindle motor to retract the heads to the ramp in the event of unexpected power loss, the tiny spindle motor used in the Microdrive did not provide enough room for windings to generate the necessary back electromotive force (back-EMF) to get the job done (even though the spinning disk does in fact have enough energy to do so). A highly efficient pulsed capacitive retract system was developed to perform this function in the Microdrive. Storage capacitors for power-off retract ended up consuming considerable space in the drive, and the pulsed retract system helped minimize the space needed for capacitors.

Another technology from the IBM 2.5-inch TravelStar line that was successfully miniaturized for the Microdrive was the bidirectional inertia latch, which made the Microdrive quite robust against mechanical shock. Earlier inertia latches were less reliable and could under some circumstances allow a head parked on the ramp to land on the disk during a mechanical shock (for example, due to dropping the drive) and subsequently stick to the disk, rendering the drive dead. Microdrive’s optimally scaled bidirectional latch solved this problem. This latch, along with the fluid bearing spindle motor used in later generations of the Microdrive, allowed the Microdrive to be the industry’s most shock resistant drive, with a rating of over 1,000G for non-operational shock.

Intended Markets

In 1998, one megapixel digital cameras were introduced, signaling the transition of the digital camera from ‘tech gadget’ to a high quality image capture device that would eventually become a wholesale replacement for the film camera. Digital cameras were the first target market for the Microdrive, and the necessary CF type II slots for the Microdrive were included in many of the higher quality cameras over the next decade. Although one-inch HDDs only captured a small fraction of the storage business for cameras, this market was vital to the launch of the Microdrive as a product. In the late 1990s, one-inch HDDs not only offered higher capacity at a better price than flash cards, but also had superior write performance, enhancing the speed at which digital cameras could acquire and store pictures.

Early MP3 players based on solid state flash memory had only enough memory (typically 16-64MB) for a few songs, which greatly limited their attractiveness. Innovative caching approaches solved power consumption issues for HDDs in MP3 players, giving players based on HDDs the same long battery life as those that used flash. In the late 1990s, IBM Fellow Steve Hetzler recognized that a small HDD could be an ideal storage medium for handheld MP3 players. IBM pursued the idea of HDD-based MP3 players with multiple main-line consumer electronics companies, but was rebuffed by all of them – the industry believed the CD-based MP3 players were the best choice, and introduced them with limited success.

Apple, not yet a major player in consumer electronics, was not approached, but understood on its own the potential market for HDD based digital music players. Apple introduced its first iPod using a Toshiba 1.8-inch 5GB HDD in October 2001.

As Jon Rubinsteen, the inventor of the IPod said about the state of disk storage in 2001: “But the key element [to making an iPod] was the drive,” he insists. “Before that, we had two choices – do a big clunky device or do a device that held a dozen songs. Neither made sense. But once I saw the 1.8-inch drive I said, Okay, now I know how to do i?” [Perry, T.S., ‘From Podfather to Palm’s Pilot,’ IEEE Spectrum, September 2008]

The iPod was an instant success and Apple went on to dominate the market for first for HDD based and then for flash memory based MP3 players (see e.g. Five years of iPod, Macworld, October 23, 2006].

In 2004, the Apple iPod mini was introduced using 2 and 4GB (and later 6GB) versions of the IBM Microdrive, which resulted in the highest sales volumes that the Microdrive ever reached. As one-inch HDD volumes grew, success no longer depended on removability and compatibility with the CF standard. Many of the one-inch HDDs designed into digital music players were embedded versions with a flex cable connection and no CF connector. Although flash memory eventually replaced one-inch HDDs in compact digital music players, HDDs played an important role in the history of these devices.

The Era of One-Inch HDDs

IBM introduced the Microdrive at 170MB-340MB in 1999 and the last model had 8GB capacity point in late 2006. In 2003, the IBM HDD business was merged with that of Hitachi, to form Hitachi Global Storage Technologies; Microdrives were sold under the Hitachi label starting in 2003. Seagate and Cornice had 12GB models announced in early 2007. As of mid 2007, no HDD supplier continued to produce one-inch HDDs. Cornice announced discontinuation of operations in February 2007.

HDD vs. Solid State Data Storage

The story of one-inch inch HDDs would be incomplete without a comparison to solid state NAND flash memory. In the beginning, the Microdrive had better write performance than flash, memory enabling digital cameras to capture more photos in a given time. However, that advantage eroded as flash write time improved at much faster rate than the data transfer rate for HDDs.

While solid state flash memory has superior mechanical durability, it suffers from a limited number of write cycles (unlike HDDs, which allow unlimited writing and rewriting of data). However, in many of the key markets for portable storage, like digital cameras and music players, flash memory (at 10,000+ write cycles) had enough write cycles for most customers.

The major disadvantage of one-inch inch HDDs is the fixed cost of the mechanical components (which includes two motors) and electronics needed to create a complete HDD, compared to the relative small overhead needed by flash memory. The fixed costs of an HDD do not scale down much with physical size; in fact, miniaturization of these components for one-inch HDDs resulted in somewhat higher cost than for larger HDDs. Lack of comparable overhead meant that flash memory could scale down to small capacity points at much lower cost than a one-inch HDD, and thereby always commanded the majority of the market share at small capacities. Large capacities are where HDDs continue to have significant price advantage over flash memory. Late in the first decade of the new millennium, progress in flash technology had moved the crossover point between flash memory and HDD to the capacity points that one-inch HDDs offered; hence their demise at that time.

Technology has continued to progress to the detriment of all HDD form factors less than two inches. The last remaining small form factor, 1.8-inch, is less than 0.5% of the 2012 market and absent a market breakthrough is expected to cease production in 2013. It appears that HDDs and flash memory will coexist in the foreseeable future but as the technology for both both types of data storage continue to progress, the crossover point between HDD and flash memory could change again, depending on which technology progresses faster in GB/$.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter