R&D: Solid State Dewetting of Thin Plasmonic Films Under Focused cw-Laser Irradiation

Investigated effect of solid-state dewetting in Au thin films, as function of local temperature, film thickness and substrate adhesion

By Francis Pelletier | January 2, 2018 at 2:26 pmActa Materialia as published an article written by William M. Abbott, Simon Corbett, Graeme Cunningham, School of Physics, CRANN and AMBER, Trinity College Dublin, Dublin 2, Ireland, Amanda Petford-Long,Material Science Division, Argonne National Laboratory, Lemont, IL 60439, USA, and Department of Materials Science and Engineering, Northwestern University, Evanston, IL 60208, USA, Sheng Zhang,Material Science Division, Argonne National Laboratory, Lemont, IL 60439, USA, John F. Donegan, and David McCloskey, School of Physics, CRANN and AMBER, Trinity College Dublin, Dublin 2, Ireland.

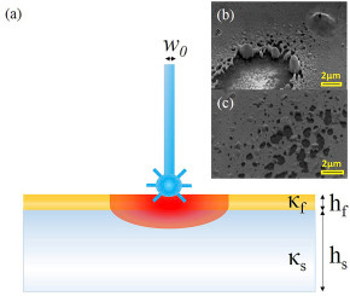

(a) schematic of cw-laser-induced heating in Au thin film;

(b) high-angle SEM image of resultant dewetted area in 50 nm Au film;

(c) high-angle SEM image of resultant dewetted area in 50 nm Au film

with a 2 nm Ti adhesion layer.

Abstract: “Elevated temperatures and large thermal gradients are a significant source of component failure in microelectronics, and are the limiting factor in heat-assisted magnetic recording (HAMR). We have investigated the effect of solid-state dewetting in Au thin films, as a function of local temperature, film thickness, and substrate adhesion. In this work, a localized temperature rise is induced in thin (≤50nm) polycrystalline Au films on SiO2 substrates via focused continuous-wave laser irradiation at 488nm. The magnitude and distribution of the total temperature rise is measured using CCD-based thermoreflectance. This also allows a sensitive measurement of the temperature at which dewetting occurs, showing that for thin Au films without adhesion layers, rapid dewetting can occur at temperatures as low as 50°C, which corresponds with an absorbed laser power of 4mW. The time decay of the reflected light from the illuminating laser is used to monitor locally the dynamics of solid state dewetting. TEM diffraction analysis shows significant changes in the microstructure and crystallographic texture of the films as far as 10μm away from the illuminated area. The use of a thin metallic adhesion layer (such as Ti or Cr) is shown to significantly improve the adhesion of the Au to the substrate, inhibit grain growth, reduce the tendency towards dewetting, and to allow the film to develop a pseudo-biaxial texture.“

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter