Potential Record Capacity of 330TB on Tape Cartridge by Sony With Areal Density of 201Gb/in²

Using IBM newly R/W heads, advanced servo control technologies and signal-processing algorithms

This is a Press Release edited by StorageNewsletter.com on August 8, 2017 at 2:24 pmPress release from Sony:

Sony Corporation developed, in collaboration with IBM Research, located in Zurich, Switzerland, a magnetic tape storage technology with the industry’s highest (1) recording areal density for tape storage media, at 201Gb/in².

This achievement was made possible by bringing together Sony’s new magnetic tape technology employing lubricant with IBM Research – Zurich’s newly developed write/read heads, advanced servo control technologies and signal-processing algorithms.

The recording areal density of 201Gb/in² is approximately 20x greater than conventional (2) magnetic tape storage media (9.6Gb/in²). The resulting technology can support high-capacity storage of approximately 330TB (3) per cartridge, whereas conventional technology can only handle 15TB per data cartridge.

These development results were jointly announced with IBM Research – Zurich on Wednesday, August 2, 2017 at The 28th Magnetic Recording Conference (TMRC 2017) at the Tsukuba International Conference Center in Tsukuba, Japan.

In recent years, developments in the IoT, the popularization of cloud services, and the leveraging of big data have helped to create new markets, resulting in increased demand for high-capacity storage media. Moreover, the importance of storage is being reaffirmed in terms of ensuring reliable recovery of data in information systems such as databases and servers, as well as safe management of information. It is against this background that magnetic tape shows great potential as a storage media thanks to its various strengths, including its capacity for storing data over long periods of time, low power consumption, low cost, and space saving capabilities.

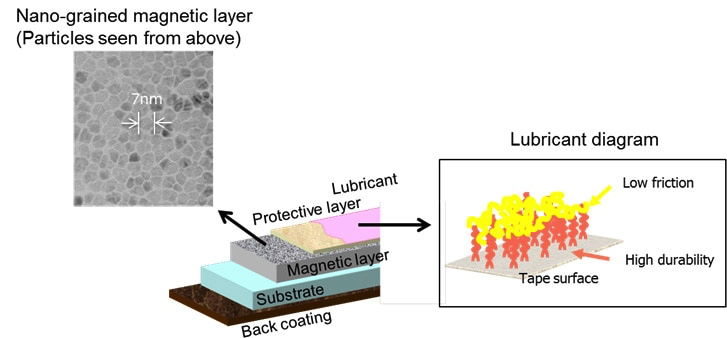

Closing the gap (spacing) between the magnetic tape and magnetic head is critical to achieving high-density recording capabilities for tape storage media. Reduced spacing entails increased friction at contact points between the tape surface and magnetic head, however, friction must be reduced and the tape surface must smoothly run along the magnetic head to enable high-capacity writing and reading at a high speed. Upon establishing this new magnetic tape technology, Sony developed a lubricant that is applied between the tape surface and magnetic head. This low-friction lubricant reduces friction between the tape surface and magnetic head, and also features a highly durable bond between the lubricant and magnetic layer of the tape.

Furthermore, this new technology made it possible to create a nano-grained magnetic layer (4) with microscopic magnetic particles in extended tape length. Conventionally, a common problem is non-uniform crystalline orientation and disparities in grain sizes due to impurity gas generated from the surface of equipment during magnetic layer formation. A newly developed processing technology that reduces impurity gas is used in conjunction with sputter deposition, (5) a method of forming a nano-grained magnetic layer with an average grain size of 7nm, thereby resulting in extended tape length. With these advancements in processing technology, the foundation has been laid for production of cartridges that can hold more than 1,000 meters of tape.

(1) On magnetic tapes. As of announcement on August 2, 2017.

(2) When compared with the IBM TS1155 tape drive, JD cartridge (non-compressed), the newest enterprise tape system.

(3) Assuming the same format overheads as the TS1155 format and taking into account the 6.4% increase in tape length enabled by the thinner demo tape. A TS1155 JD cartridge, can hold 15TB of uncompressed data in a 4.29 in. x 4.92 in. x 0.96 in. (109.0 mm x 125 mm x 24.5 mm) form actor.

(4) Nano-grained magnetic layer Sony original thin layer tape formation technology which forms a layer of uniform, nanometer-scale magnetic particles on the substrate. The technology features optimized sputter conditions which minimize surface unevenness on the substrate, resulting in a uniform deposition of microscopic magnetic particles.

(5) Sputter deposition: A thin layer formation method where electrostatic discharge is used to force argon (Ar) ions to collide with the source material (target), and the sputtered material forms a deposition on the substrate to create a thin layer.

Sony will build on this new development to forge ahead with development of magnetic tape technologies, aiming to commercialize next-generation tape storage media capable of high-capacity data recording and achieve even higher recording density.

Press release from IBM:

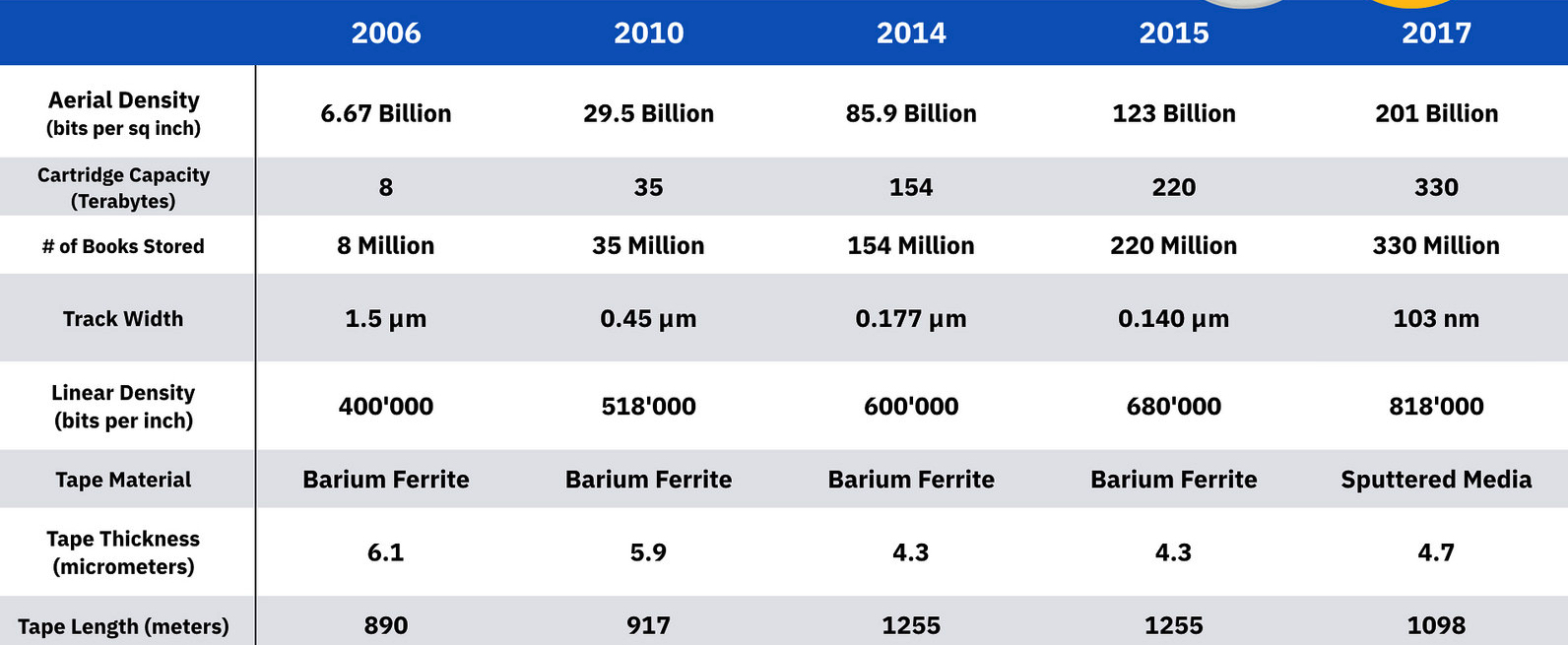

IBM Research scientists achieved a new world record in tape storage – their fifth since 2006.

The new record of 201Gb/in² in areal density was achieved on a prototype sputtered magnetic tape developed by Sony Storage Media Solutions.

The scientists presented the achievement at the 28th Magnetic Recording Conference (TMRC 2017).

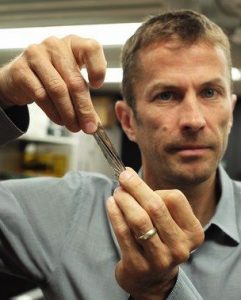

In this photo, IBM scientist Dr. Mark Lantz, holds a one square inch piece of Sony Storage Media Solutions sputtered tape, which can hold 201GB, a new world record.

(Photo credit: IBM Research)

Tape storage is currently a secure, energy efficient and cost-effective solution for storing enormous amounts of backup and archival data, as well as for new applications such as big data and cloud computing.

This new record areal recording density is more than 20 times the areal density used in current state of the art commercial tape drives such as the IBM TS1155 enterprise tape drive, and it enables the potential to record up to about 330TB of uncompressed data* on a single tape cartridge that would fit in the palm of your hand. 330TB of data are comparable to the text of 330 million books, which would fill a bookshelf that stretches slightly beyond the northeastern to the southwestern most tips of Japan.

IBM’s Tale of the Tape

More than 60 years of innovation

With this achievement, IBM scientists demonstrate the viability of continuing to scale the tape roadmap for another decade.

“Tape has traditionally been used for video archives, backup files, replicas for DR and retention of information on premise, but the industry is also expanding to off-premise applications in the cloud,” said IBM fellow Evangelos Eleftheriou. “While sputtered tape is expected to cost a little more to manufacture than current commercial tape that uses Barium ferrite (BaFe), the potential for very high capacity will make the cost per terabyte very attractive, making this technology practical for cold storage in the cloud.”

To achieve 201Gb/in², IBM researchers developed several new technologies, including:

• Innovative signal-processing algorithms for the data channel, based on noise-predictive detection principles, which enable reliable operation at a linear density of 818,000 bits per inch with an ultra-narrow 48nm wide tunneling magneto-resistive (TMR) reader.

• A set of advanced servo control technologies that when combined enable head positioning with an accuracy of better than 7nm. This combined with a 48nm wide (TMR) HDD drive read head enables a track density of 246,200 tracks per inch, a 13-fold increase over a state of the art TS1155 drive.

• A novel low friction tape head technology that permits the use of very smooth tape media

IBM has been working closely with Sony Storage Media Solutions for several years, particularly on enabling increased areal recording densities. The results of this collaboration have led to various improvements in the media technology, such as advanced roll-to-roll technology for long sputtered tape fabrication and better lubricant technology, which stabilizes the functionality of the magnetic tape.

Many of the technologies developed and used in the areal density demonstrations are later incorporated into future tape products.

Two notable examples from 2007 include an advanced noise predictive maximum likelihood read channel and first generation BaFe tape media.

IBM has a long history of innovation in magnetic tape storage. Its first commercial tape product, the 726 Magnetic Tape Unit, was announced more than 60 years ago. It used reels of half-inch-wide tape that each had a capacity of about 2MB.

The areal density demonstration announced represents a potential increase in capacity of 165,000,000 times compared with this first tape drive product.

* Assuming the same format overheads as the TS1155 format and taking into account the 6.4% increase in tape length enabled by the thinner demo tape. A TS1155 JD cartridge, can hold 15TB of uncompressed data in a 4.29 in. x 4.92 in. x 0.96 in. (109.0 mm x 125 mm x 24.5 mm) form factor

Resources:

201Gb/in² Recording Areal Density on Sputtered Magnetic Tape, Simeon Furrer, Mark A. Lantz, Peter Reininger, Angeliki Pantazi, Hugo E. Rothuizen, Roy D. Cideciyan, Giovanni Cherubini, Walter Haeberle, Evangelos Eleftheriou, Junichi Tachibana, Noboru Sekiguchi, Takashi Aizawa, Tetsuo Endo, Tomoe Ozaki, Teruo Sai, Ryoichi Hiratsuka, Satoshi Mitamura, and Atsushi Yamaguchi, DOI 10.1109/TMAG.2017.2727822, IEEE Transactions on Magnetics,

More on the history of IBM and magnetic tape storage

More details about magnetic tape technology

Video

Comments

Up to now, FujiFilm was the preferred supplier of tape cartridges to IBM.

Sony revealed in May 2014 a tape technology able to store 185TB in an LTO cartridge. I was followed rapidly by an answer from FujiFilm and IBM stating to be able to put native 154TB into the same volume.

Remember also that, in 2015, Big Blue, this time in collaboration with FujiFilm, demonstrated the potential for recording at an areal density of 123Gb/in2 using a prototype BaFe tape fabricated using low cost particulate coating technology. It was estimated that this areal density will enable cartridge capacities of up to 220TB uncompressed.

Consequently 220TB was the highest capacity revealed for a tape cartridge, but never integrated into a commercial products.

Now the record is 330TB without compression, apparently on a 1,098 meters (more tan one kilometer!) magnetic roll with Sony based on a tape with 103nm track width and 818,000bpi linear density on sputtered - and not BaFe - media of 4.7μm thickness, for an aerial density of 201 billion bits per square inch. And once more no availability is announced.

What's actually available is a record native of only 15TB capacity into proprietary cartridges inserted into IBM TS1155 drive, and 6TB on LTO-7, both of them using half-inch tape. Per comparison, HDDs culminate at 12TB.

Historically, the first tape drive for a computer was the UNISERVO from Remington Rand, Inc.'s Eckert-Mauchly Division. One year later IBM launched in May 21, 1952 its first unit, the model 726 Magnetic Tape Reader/Recorder, with an initial capacity of about 2MB per reel, four years before the first HDD, IBM Ramac, at 5MB.

Magnetic tape media and heads are the two key elements to improve the performance of longitudinal magnetic tape media. That's why, on one side, IBM, manufacturer of tape drives, including heads and all the mechanism associated, but not producing tape media at all, and on the other side, Fujifilm and Sony, in tape media, collaborating with Big Blue since many years to enhance their common solution.

Subscribe to our free daily newsletter

Subscribe to our free daily newsletter